UPS Battery Maintenance: A Comprehensive Guide for Reliable Power Protection

Introduction

In today’s always-on economy, uninterrupted power supply is no longer optional—it is a business necessity. From data centers to healthcare facilities, telecom networks, and industrial plants, organizations rely on UPS (Uninterruptible Power Supply) systems to bridge gaps during outages and protect critical equipment.

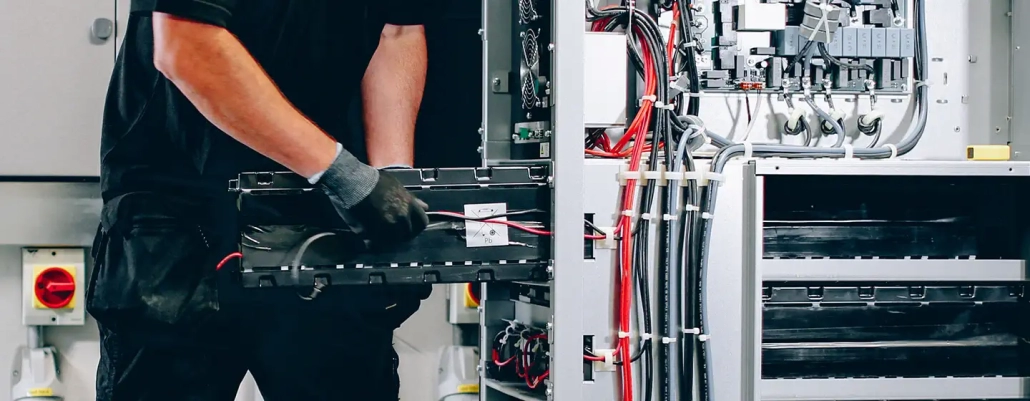

At the core of every UPS system lies its batteries. Even the most advanced UPS unit cannot deliver reliable backup if its batteries are not properly maintained. That is why UPS battery maintenance is essential—not only for minimizing downtime but also for maximizing the return on investment and ensuring compliance with operational requirements.

This guide explores battery types, core maintenance practices, and industry-specific considerations, offering a practical roadmap for businesses that prioritize uptime and resilience.

- Understanding UPS Battery Types and Their Maintenance Needs

1.1 Lead-Acid Batteries (VRLA and Flooded)

Lead-acid batteries have long been the standard for UPS systems. VRLA (Valve Regulated Lead Acid) models dominate in small to medium systems, while flooded types are common in large installations.

- Common failure modes: electrolyte drying, plate sulfation, and terminal corrosion.

- Maintenance essentials:

- Regular voltage and internal resistance measurements.

- Checking electrolyte levels (for flooded types).

- Tightening and cleaning connections to prevent overheating.

- Ensuring adequate ventilation to avoid thermal buildup.

1.2 Lithium-Ion Batteries

Lithium-ion technology is rapidly gaining traction in UPS systems, particularly where reliability and lifecycle cost are priorities.

- Advantages:

- Longer cycle life (up to twice or more compared to lead-acid).

- Lower maintenance frequency.

- Built-in Battery Management Systems (BMS) for self-diagnostics.

- Maintenance focus:

- Reviewing BMS logs and ensuring firmware is up to date.

- Checking charge/discharge balance across cells.

- Verifying integration with the UPS monitoring system.

👉 For organizations requiring short-time backup, consider exploring dedicated solutions like lithium UPS battery systems, designed to combine reliability with reduced maintenance demands.

- Core UPS Battery Maintenance Practices

No matter the chemistry, certain maintenance routines are universal. Implementing them consistently reduces unexpected failures and extends service life.

2.1 Routine Visual and Electrical Inspections

- Inspect terminals for discoloration or corrosion.

- Verify cabling is intact and properly torqued.

- Measure float voltage and charging current to ensure the UPS is operating within manufacturer guidelines.

2.2 Environmental Control

- Temperature: Lead-acid batteries perform best at ~77°F (25°C). Every 15°F (8°C) increase above this can cut lifespan by 50%. Lithium batteries are more tolerant but still benefit from controlled environments.

- Humidity: Keep within 20–80% RH to prevent corrosion.

- Dust and contaminants: Clean UPS rooms regularly to reduce conductive debris buildup.

2.3 Capacity and Discharge Testing

- Conduct load tests under realistic conditions to confirm runtime expectations.

- Compare measured capacity with baseline data; replace batteries once capacity falls below 80%.

- Schedule preventive replacements before critical thresholds are reached.

2.4 Cleaning and Safety Measures

- Use dielectric grease to protect terminals against oxidation.

- Employ personal protective equipment (PPE) when handling flooded lead-acid units.

- Dispose of spent batteries through certified recycling programs to remain compliant.

- Industry-Specific Maintenance Considerations

Each industry imposes unique demands on UPS systems. While the fundamentals of battery maintenance remain consistent, risk tolerance and operational requirements shape how frequently checks and replacements should be carried out.

3.1 Data Centers

Data centers operate on strict uptime requirements, where even a few minutes of downtime can result in substantial financial loss.

- Best practices include predictive replacement cycles based on trend data from load tests.

- Parallel system testing ensures redundancy is reliable.

- Capacity forecasting tools help plan battery replacement before degradation compromises runtime.

👉 For more in-depth strategies, see: How Often Should Data Centers Replace UPS Batteries? A Strategic Approach to Lifecycle Planning.

3.2 Telecom Networks

Telecom operators manage distributed infrastructure, often in unmanned or remote locations.

- Low-maintenance chemistries such as lithium are increasingly favored.

- Maintenance programs should emphasize environmental resilience—temperature swings, dust, and restricted access all require proactive planning.

3.3 Healthcare Facilities

Hospitals and clinics cannot afford any power interruptions during critical procedures.

- Batteries must undergo higher-frequency discharge testing compared to other industries.

- Dual-redundant battery strings are often deployed, and both require synchronized maintenance.

3.4 Industrial and Manufacturing

In manufacturing plants, high load surges and harsh conditions stress UPS batteries differently.

- Routine torque checks on cables are essential due to vibration and heavy load shifts.

- Regular discharge testing validates that batteries can support large machinery startups.

- Maintenance Frequency and Lifecycle Planning

Daily/Weekly

- Visual inspections for leaks, corrosion, or swelling.

- Quick voltage checks and log review.

Quarterly/Biannual

- Perform detailed torque checks on terminals.

- Run partial load tests to measure capacity.

- Verify charger calibration.

Annual

- Conduct full discharge tests.

- Review environmental data logs.

- Reassess lifecycle planning for replacements.

Replacement Cycles

- Lead-acid: Typically 3–5 years under controlled conditions.

- Lithium-ion: Often 8–12 years, with reduced replacement frequency and lower lifetime maintenance costs.

Conclusion

UPS systems are only as reliable as the batteries that power them. A structured, proactive approach to UPS battery maintenance helps businesses avoid unexpected downtime, safeguard critical operations, and control long-term costs.

By tailoring maintenance strategies to battery chemistry and industry application, organizations can achieve both resilience and efficiency. Whether in data centers, telecom networks, healthcare, or industrial settings, investing in preventive maintenance is the surest way to protect business continuity.